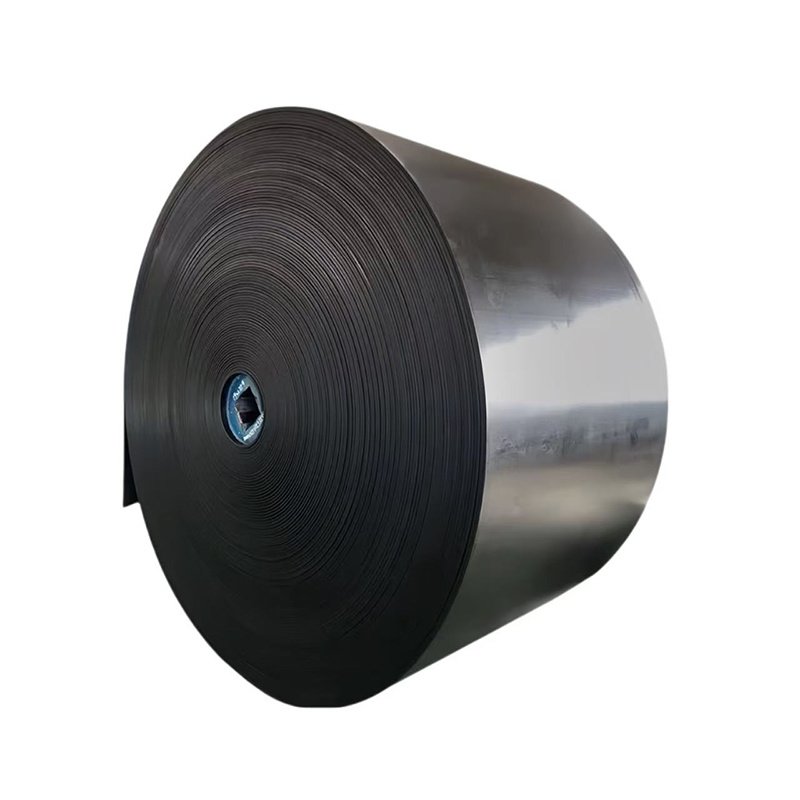

In bustling ports, deep underground mines, high-speed food processing plants, and efficient logistics centers, an invisible “artery” pulsates day and night, connecting raw materials, semi-finished, and finished products to form the cornerstone of modern industrial production—this is the rubber conveyor belt. It is not merely a simple material handling tool but a key piece of equipment for enhancing efficiency, reducing costs, and achieving automation.

I. Core Value: Multiple Roles Beyond “Transportation”

The application of rubber conveyor belts in industry has long surpassed the simple function of “conveying,” playing multiple core roles:

- Efficiency Engine: It enables the continuous, automated flow of materials between different workstations, workshops, and even entire plant areas, completely replacing inefficient and costly manual handling. It is an indispensable component of modern production lines.

- Cost Controller: By significantly reducing labor, shortening operation times, and lowering packaging requirements, conveyor belt systems bring substantial long-term cost benefits to enterprises.

- Safety Guardian: In heavy-load, high-temperature, or hazardous environments, using conveyor belts prevents direct human contact with materials, effectively ensuring personnel safety and reducing material loss.

- Process Integration Platform: During conveyance, it can simultaneously complete various processes such as sorting, weighing, cooling, and inspection, achieving integrated production where “conveying is processing.”

II. Key Characteristics: The Core Determinants of Performance and Applicability

A high-quality industrial rubber conveyor belt is the product of the perfect combination of its physical properties and specific working conditions, primarily considering the following aspects:

- Belt Structure and Material:

- Carcass Material: Common materials like polyester canvas (EP), nylon canvas (NN), or steel cord (ST) provide different tensile strengths, troughability, and impact resistance to suit varying load demands.

- Cover Rubber: The top cover rubber withstands material impact and abrasion, while the bottom cover rubber interacts with the idlers. Its compound is tailored to specific requirements such as wear resistance, tear resistance, heat resistance, oil resistance, or food-grade standards.

- Functional Enhancements:

- Heat Resistance: Used for conveying high-temperature materials like sintered ore and cement clinker, capable of withstanding temperatures up to several hundred degrees Celsius without failure.

- Flame Resistance and Anti-Static Properties: Essential safety features in flammable and explosive environments such as coal mines and chemical plants.

- Food-Grade Certification: White or light-colored belts compliant with standards like FDA and EU ensure no product contamination in the food and pharmaceutical industries.

- Non-Slip Patterns: Designs like herringbone and diamond patterns effectively prevent materials from slipping during inclined conveyance.

III. Application Scenarios: The Ubiquitous Backbone of Industry

- Heavy Industry and Mining: In ports, power plants, and mines, high-strength, impact-resistant steel cord conveyor belts undertake the long-distance, high-volume transportation of bulk materials like ore and coal.

- Food and Agricultural Processing: Food-grade conveyor belts are widely used in sorting, washing, cooking, and packaging lines for beverages, confectionery, meat, and fruits, requiring hygiene, easy cleaning, and being non-toxic and odorless.

- Logistics and Parcel Sorting: Lightweight, high-speed, low-noise conveyor belt systems form the skeleton of modern parcel distribution centers, enabling rapid flow and precise sorting of packages.

- Light Industry and Electronics Manufacturing: In workshops for electronic assembly and appliance production, precision conveyor belts smoothly transport delicate components, ensuring continuity and efficiency in the production process.

IV. Future Trends: Intelligence and Sustainability

With the advancement of Industry 4.0, rubber conveyor belts are evolving to a higher level:

- Intelligent Integration: Built-in sensors can monitor belt tension, temperature, and tearing conditions in real-time, enabling predictive maintenance and preventing unplanned downtime.

- Green and Environmental Protection: Development of eco-friendly belts made from recyclable materials, alongside energy-efficient, long-life products, responding to the global call for sustainable development.

- Customized Solutions: Providing deeply customized products and system design solutions for the special needs of specific industries (e.g., extreme cold resistance, chemical corrosion resistance).

Conclusion

The rubber conveyor belt, this silent “artery” flowing through factories, is a physical microcosm of the efficiency and automation of modern industry. Choosing a suitable conveyor belt is not just about selecting a component; it is about choosing a reliable and efficient strategic partner for the entire production system. On the path to the future of smart manufacturing, this fundamental yet crucial technology will continue to evolve, silently driving the world forward.